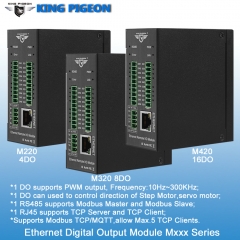

8DO+8Relay Digital Output Module (RS485/Ethernet)

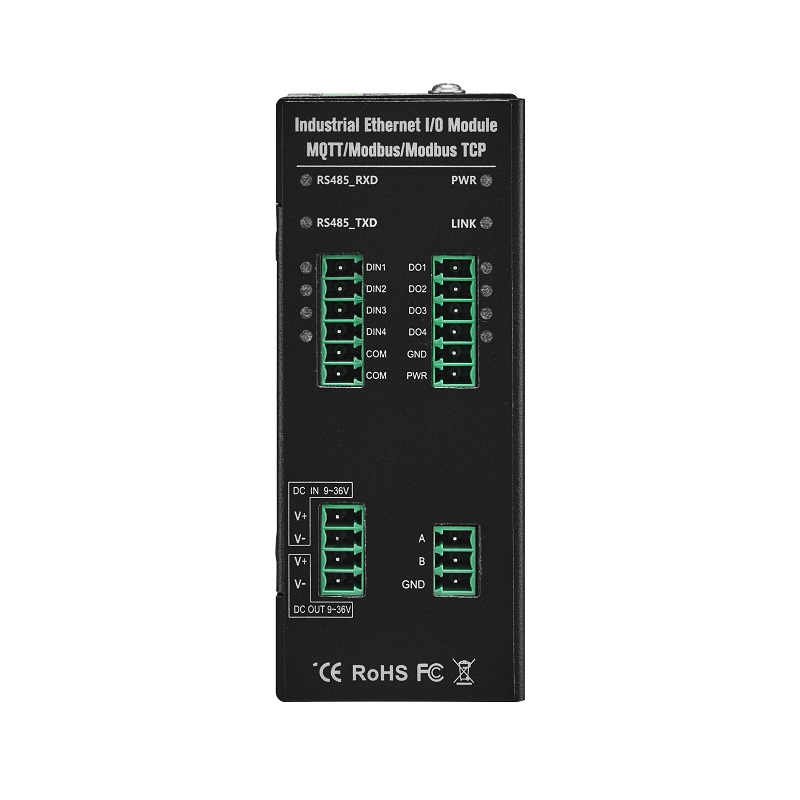

The M320R Ethernet Remote I/O Module is an industrial class, isolated designed, high reliability, high stability and high precision data acquisition module, embedded 32-Bit High Performance Microprocessor MCU, Integrated 1-2 Industrial 10/100M adaptive Ethernet module inside. It provides multi I/O, supports standard Modbus TCP, can be intergraded into SCADA, OPC server, and other automation systems. It is design for working in the harsh industrial application environment, widely used in a variety of industrial automation, security monitoring system, automatically measurement and control system.

The M320R Ethernet Remote I/O module provides a RS485 interface, through the RS485 bus, it can cascade Modbus RTU I/O devices or Modbus RTU meters, e.g.: a variety of digital input or digital outputs, analog inputs or outputs, thermal resistance IO module combination, save costs. At the same time, the Ethernet Remote I/O module has register mapping function, the cascade Modbus RTU I/O data are automatically collected to the mapping memory area, the Modbus TCP Client query without waiting then can get a quick response to meet the industrial timely requirements.

The M320R Ethernet Remote I/O module provides 8 digital outputs, supports 10Hz~300Khz high speed pulse output and 8 relay outputs. All of the I/O with high sampling frequency and special filtering strategy to ensure it’s reliable.

2. Wide range power supply 12 ~ 36VDC with over voltage and phase-reversal protection;

3. Management and configuration via LAN connection configuration software for easy operation and maintenance;

4. Integrated 10/100M adaptive Ethernet module, supports Modbus TCP protocol;

5. 8 digital output and 8 relay output, DO supports 10Hz~300KHz high speed pulse output;

6. High sampling frequency and special filtering strategy to ensure reliability;

7. 1 RS485 Serial port, supports Modbus RTU/ASCII Master, can extend I/O modules;

8. Supports register mapping function and extend I/O inquiry strategy;

9.Provides 1 channel 12~36VDC power source output for external device, saving wiring cost;

10.LED instructions work status, with reset button to reset, easy on-site installation and commissioning;

11.Using metal shell, protection class IP30. Metal shell and system security isolation, especially suitable for industrial applications in the field;

12.Small size, L105 * W88 * H30mm, compatible wall installation and DIN35mm industrial rail installation.

|

Ethernet Remote I/O Module Specifications |

|

|

• Digital Output |

|

|

Type |

Sink |

|

I/O Mode |

DO or Pulse Output |

|

Pulse Output Frequency |

10Hz~300KHz(Only the 1st Channel can be used as high speed pulse outputs) |

|

Over-Voltage Protection |

50 VDC |

|

Over-Temperature Shutdown |

175°C (typical), 150°C (min.) |

|

Load Current |

Max. 500 mA per channel |

|

Digital sampling frequency |

500Hz |

|

Isolation |

If DO is Sink type, then no isolation. If it is Relay, then is electrical isolation. |

|

• Working Power Requirements |

|

|

Input Voltage |

12 to 36 VDC, Peak Voltage:+40VDC, Power consumption: Less than 3W; |

|

Input Current |

139 mA @ 24 VDC |

|

• LAN |

|

|

Ethernet |

10/100 Mbps, RJ45 ports |

|

Protection |

15KV ESD Protection |

|

Protocols |

Modbus TCP, TCP/IP,MQTT, TCP Server, TCP Client |

|

Max. TCP Connection |

5 |

|

• Serial Port |

|

|

RS485 |

MODBUS- RTU Protocol, Modbus-ASCII Protocol |

|

Protection |

15KV ESD Protection |

|

Modbus Slave address |

1~255 |

|

Baud Rate |

1200,2400,4800,9600,19200,38400,57600,115200,128000Bps; |

|

Mapping registers |

Bit Type: 300 Registers, 16-Bit Type: 300 Registers.300 |

|

• Physical Characteristics |

|

|

Wiring |

I/O cable max. 14 AWG |

|

Dimensions |

105 x 88 x 30 mm |

|

Weight |

Under 205 g |

|

Mounting |

DIN rail or wall |

|

• Environmental Limits |

|

|

Operating Temperature |

Standard Models: -10 to 60°C (14 to 140°F) |

|

Storage Temperature |

-40 to 85°C (-40 to 185°F) |

|

Ambient Relative Humidity |

5 to 95% (non-condensing) |

|

Altitude |

Up to 3000 m |

Typically applications:

1. BTS Monitoring;

2. Security Alarm System applications;

3. Supervision and monitoring alarm systems;

4. Automatic monitoring system;

5. Vending Machines security protection;

6. Pumping Stations, Tanks, Oil or Water levels;

7. Buildings and Real Estate;

8. Weather Stations;

9. River Monitoring and Flood Control;

10. Oil and gas pipelines;

11. Corrosion protection

12. Temperatures, water leakage applications;

13. Wellheads, boat, vehicle;

14. Energy saving, street lights control system;

15. Valve controls;

16. Transformer stations;

17. Unmanned machine rooms;

18. Control room application;

19. Automation System, M2M;

20. Access Control System;

21. PLC Gateway, PLC Remote Monitoring.

The M320R Ethernet Remote I/O Module is an industrial class, isolated designed, high reliability, high stability and high precision data acquisition module, embedded 32-Bit High Performance Microprocessor MCU, Integrated 1-2 Industrial 10/100M adaptive Ethernet module inside. It provides multi I/O, supports standard Modbus TCP, can be intergraded into SCADA, OPC server, and other automation systems. It is design for working in the harsh industrial application environment, widely used in a variety of industrial automation, security monitoring system, automatically measurement and control system.

The M320R Ethernet Remote I/O module provides a RS485 interface, through the RS485 bus, it can cascade Modbus RTU I/O devices or Modbus RTU meters, e.g.: a variety of digital input or digital outputs, analog inputs or outputs, thermal resistance IO module combination, save costs. At the same time, the Ethernet Remote I/O module has register mapping function, the cascade Modbus RTU I/O data are automatically collected to the mapping memory area, the Modbus TCP Client query without waiting then can get a quick response to meet the industrial timely requirements.

The M320R Ethernet Remote I/O module provides 8 digital outputs, supports 10Hz~300Khz high speed pulse output and 8 relay outputs. All of the I/O with high sampling frequency and special filtering strategy to ensure it’s reliable.

2. Wide range power supply 12 ~ 36VDC with over voltage and phase-reversal protection;

3. Management and configuration via LAN connection configuration software for easy operation and maintenance;

4. Integrated 10/100M adaptive Ethernet module, supports Modbus TCP protocol;

5. 8 digital output and 8 relay output, DO supports 10Hz~300KHz high speed pulse output;

6. High sampling frequency and special filtering strategy to ensure reliability;

7. 1 RS485 Serial port, supports Modbus RTU/ASCII Master, can extend I/O modules;

8. Supports register mapping function and extend I/O inquiry strategy;

9.Provides 1 channel 12~36VDC power source output for external device, saving wiring cost;

10.LED instructions work status, with reset button to reset, easy on-site installation and commissioning;

11.Using metal shell, protection class IP30. Metal shell and system security isolation, especially suitable for industrial applications in the field;

12.Small size, L105 * W88 * H30mm, compatible wall installation and DIN35mm industrial rail installation.

|

Ethernet Remote I/O Module Specifications |

|

|

• Digital Output |

|

|

Type |

Sink |

|

I/O Mode |

DO or Pulse Output |

|

Pulse Output Frequency |

10Hz~300KHz(Only the 1st Channel can be used as high speed pulse outputs) |

|

Over-Voltage Protection |

50 VDC |

|

Over-Temperature Shutdown |

175°C (typical), 150°C (min.) |

|

Load Current |

Max. 500 mA per channel |

|

Digital sampling frequency |

500Hz |

|

Isolation |

If DO is Sink type, then no isolation. If it is Relay, then is electrical isolation. |

|

• Working Power Requirements |

|

|

Input Voltage |

12 to 36 VDC, Peak Voltage:+40VDC, Power consumption: Less than 3W; |

|

Input Current |

139 mA @ 24 VDC |

|

• LAN |

|

|

Ethernet |

10/100 Mbps, RJ45 ports |

|

Protection |

15KV ESD Protection |

|

Protocols |

Modbus TCP, TCP/IP,MQTT, TCP Server, TCP Client |

|

Max. TCP Connection |

5 |

|

• Serial Port |

|

|

RS485 |

MODBUS- RTU Protocol, Modbus-ASCII Protocol |

|

Protection |

15KV ESD Protection |

|

Modbus Slave address |

1~255 |

|

Baud Rate |

1200,2400,4800,9600,19200,38400,57600,115200,128000Bps; |

|

Mapping registers |

Bit Type: 300 Registers, 16-Bit Type: 300 Registers.300 |

|

• Physical Characteristics |

|

|

Wiring |

I/O cable max. 14 AWG |

|

Dimensions |

105 x 88 x 30 mm |

|

Weight |

Under 205 g |

|

Mounting |

DIN rail or wall |

|

• Environmental Limits |

|

|

Operating Temperature |

Standard Models: -10 to 60°C (14 to 140°F) |

|

Storage Temperature |

-40 to 85°C (-40 to 185°F) |

|

Ambient Relative Humidity |

5 to 95% (non-condensing) |

|

Altitude |

Up to 3000 m |

Typically applications:

1. BTS Monitoring;

2. Security Alarm System applications;

3. Supervision and monitoring alarm systems;

4. Automatic monitoring system;

5. Vending Machines security protection;

6. Pumping Stations, Tanks, Oil or Water levels;

7. Buildings and Real Estate;

8. Weather Stations;

9. River Monitoring and Flood Control;

10. Oil and gas pipelines;

11. Corrosion protection

12. Temperatures, water leakage applications;

13. Wellheads, boat, vehicle;

14. Energy saving, street lights control system;

15. Valve controls;

16. Transformer stations;

17. Unmanned machine rooms;

18. Control room application;

19. Automation System, M2M;

20. Access Control System;

21. PLC Gateway, PLC Remote Monitoring.